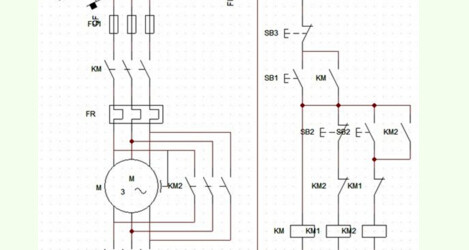

Mechanical interlocking contactor

The mechanical interlocking contactor is mainly used for AC 50Hz or 60Hz, and the rated operating voltage to 660V, rated operating current to the following 95A circuit, for motor reversible control. Its mechanical interlocking mechanism ensures the reliability of the conversion of the two reversible contactor.

Two contactor combination in the control of the motor is reversed called reversible contactor. The mechanism that is installed between two contacts, called mechanical linkage. If there is no the device, press the control button on the left of the contactor and press the control button on the right side of the contactor, the two contactors will pull in, the main circuit is short circuited. This device is to prevent and pull two contactors.

CJX2-N (LC2-D) series reversible chain AC contactor is suitable for AC 50Hz or 60Hz, voltage to 690V, current to 95A circuit, and can be used for motor reversible control. Its mechanical interlocking structure, which ensures the reliable operation of the two reversible contactor.

Products comply with GB14048.4 standards.

Some of the more commonly used models are:

CJX2-09, CJX2-12, CJX2-18, CJX2-25, CJX2-32

CJX2-40, CJX2-50, CJX2-65, CJX2-80, CJX2-95

LC2-D09, D12 LC2-, D18 LC2-, D25 LC2-, D32 LC2-

D40 LC2-, D50 LC2-, D65 LC2-, D80 LC2-, D95 LC2-

Model rated operating current AV-3A, 400V control power KW auxiliary contact number notes

400V 415V 440V 690V 230V

CJX2-09N 5.5 NC 92.2444 installation method except the screws, the installation of the 35mm

CJX2-12N 5.5 7.5 5.5 NC

CJX2-18N 7.599 1847.5 NC

CJX2-25N 255.511111115 NC

CJX2-32N 18.5 327.5151515 NC

CJX2-40N 18.52230 NO+NC addition screw is equipped with 75mm mounting rail

CJX2-50N 501522223033 NO+NC

CJX2-63N 6318.530303737 NO+NC

CJX2-80N 802237374545 NO+NC

CJX2-95N 952545454545 NO+NC

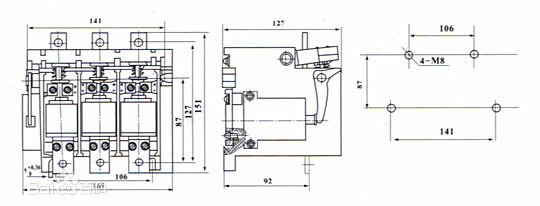

Three: CJX2-N (LC2-D) reversible AC contactor appearance and installation size

QJX2 series star delta motor starter

Large power motor starting current is very big, in order to avoid the impact of large current on the line, the motor angle method is changed to start with a certain inertia, the rotation speed of a certain inertia, then turn to the angle of the start, the starting current of the 1/3. From 3 contacts, 1 time relay and button.

QJX2 series star delta starter (hereinafter referred to as starter), is suitable for AC 50Hz or 60Hz, rated insulation voltage of 660V (690V), the AC-3 type of three-phase squirrel cage induction motor with rated working voltage of 380V, power 80KW, and the following is used to control the stator winding from “Star” to “triangle” for starting and stopping. After assembling the thermal relay of the corresponding specification, the overload protection of the motor and the related circuit can be protected.

The starter and QJX4, LC3-D have the same functional specifications can be equated with the use of.

The function and principle of Starter Motor are respectively:

1, role:

The motor starter is device for auxiliary motor starting, the motor start smoothly, little impact on the grid, but also to achieve the soft parking of motor, brake, overload and lack of protection. The motor starter is mainly used for large motor and asynchronous motor.

2, working principle:

The distance between the plate to the liquid resistance value in the starting process always meet the mechanical property requirements on the on resistance value, thereby causing the motor to obtain the maximum starting torque and the minimum starting current and starting a smooth. Specific work process is: to start the main motor active polar plate in a small power gear system driven by slowly moving, change the distance between the two plates, the string into the rotor circuit of liquid resistance value change meet the above conditions, the motor speed increased. When the distance between the two plates is the minimum, the motor speed of the motor reaches the rated speed, the liquid resistance is short, the starting process is completed, the operation state is transferred.

GV2ME series motor protective circuit breaker

Motor protector is to protect the motor, the motor is overload, lack of phase, short circuit, short circuit, over voltage, under voltage, leakage, three phase unbalance, overheating, bearing wear, stator rotor eccentricity, to alarm or protect the device.

Common types of motor protectors

1, thermal relay: Ordinary small capacity AC motor, working condition is good, there is no frequent starting and other bad conditions of the situation; because of poor accuracy, reliability can not be guaranteed, not recommended.

2, electronic type: detection of three-phase current value, the whole set current value of potentiometer or pull off code switch, circuit is generally used in analog mode, the use of anti time limit or time limit for work. Protection functions including overload, lack of phase, blocking, etc., the type of failure to use the indicator light shows that the operation of the use of digital tube display.

3, intelligent: detection of three-phase current value, the use of single-chip microcomputer, to achieve the motor intelligent integrated protection, set protection, measurement, communication, display as one. The setting current adopts digital setting, operation panel button to operate, the user can according to the specific circumstances of the motor in the field of various parameters correction setting; the use of digital tube as display window, or the use of large screen LCD display, can support a variety of communication protocols, such as ProfiBUS, ModBUS, etc., the price is relatively high, for more important occasions; high voltage motor protection are the use of intelligent protection device.

4, thermal protection: in the motor of the buried thermal element, according to the motor winding temperature of the motor, the protection effect is good, but the motor capacity is large, need to use the current monitoring type, to avoid the temperature of the motor when the temperature rises sharply, due to the delay of the temperature measurement element, resulting in motor winding damage.

5, magnetic field temperature detection: in the motor of the magnetic field detection coil and temperature measurement element, according to the motor internal rotating magnetic field changes and temperature changes in the protection, the main functions include overload, plugging, lack of phase, over heat protection and wear monitoring, protection function is perfect, the need to install magnetic field detection coil and temperature sensor.

schneider ac contactor LC1D series

LC1-D09M7C Schneider AC contactor is widely used in the power of the open circuit and control circuit. It uses the main contact to open and close circuit, with auxiliary contacts to execute control instructions. The main contact is normally open contact, and the auxiliary contact is often two pairs of normally open and normally closed function of the contact, small contactor is also often used as the intermediate relay with the main circuit. The contact of AC contactor, made of silver tungsten alloy, has good electrical conductivity and high temperature resistance.

– the contactor can be composed of a mechanical reversible interlocking magnetic starter, a star delta starter

– contactor is a protective type, and the action structure is a direct acting type, and the contact is a double breakpoint.

– has the characteristics of small size, light weight, low power consumption, long life, safe and reliable, etc.

– according to the user to choose to increase the auxiliary contact group, the air delay is a combination of a variety of first class products

– when installing, should be in accordance with the provisions of the installation, the terminal A1 of the contactor coil in line with the top of the head, consistent with human visual habits

– the contact of the metal mounting base plate shall be properly grounded

– terminal screws should be tightened, check the wiring is correct, should be in the main contact is charged and the attracting coil power several times, action test is reliable, can be put into use

If there is abnormal noise, when in use, may be a core pole on dirt wipe face, please

– use, should be regularly check the product components, the movable part is not stuck, fastening parts without loose, spare parts if there is damage, should be replaced in time

Overview of domestic and foreign Principal company products

1.ABB B series, A Series in early 1980s, the Shanghai people’s Electrical Appliance Factory, Beijing Electric Factory as a production license form, technology introduction of ABB B series has a preliminary modular structure; after the launch of the EB, EH series; 90’s launched the A series. A series contactor has 9 ~ 1050A22 current level, 8 kinds of models, the application of the environment temperature is: – 40, 70, is the characteristics of the contactor.

2 Fuji Corp’s SC-E series SC-E series is a joint venture between Changshu Switch Factory Co., Ltd. and Fuji Corp, there are 9 ~ 800A18 current rating, 10 kinds of models. In addition to the characteristics of the module, the volume is small, its bright spot. For example, the SC-E25 of the rated current 50A of 90mm x 54mm x 96mm, only for the same current rating of ABB A50D 50.6%, is a Schneider Inc LC1-D50 38.5%, with a high reliable contact performance (DC5V, 3mA).

3 Schneider Inc LC1-D Series in the early 1980s, Tin Shui 213 machine tool electric plant to introduce the Schneider Inc LC1-D series of contacts, is the first to enter the country of the contactor. At that time, LC1 by the current size of 9 ~ D 95A series and 115 ~ F 780A series. In recent years, the introduction of a current level of 9 ~ 620A20, 8 models of the LC1-D series. The product is a typical representative of the modular structure, further reducing the flying arc distance, improve the protection level, operating frequency can be as high as 3600 /h (small current specifications) or 2400 /h (large current specifications).

4 SIEMENS’s 3RT series SIEMENS 3RT series contactor inherited the 3TB’s life span, the coil module, easy to replace the advantages, and the realization of the full plastic and high protection (IP2x). Full range of 7 to 500A19 current rating, 7 kinds of models, the highest mechanical life of 30000000 times, the average power consumption of the coil is easy to be similar to the characteristics of the same.

5 domestic C J40, CJ45 series products of this series of products mainly by Shanghai Electrical Apparatus Research dominated development, Hangzhou Zhijiang switch factory, Shanghai People’s Electrical Appliance Factory, Tianjin Baili, Chint Electric Appliance Co., Ltd., the production of C J40, CJ45; Tianshui 213 factory introduced production gsc1 column; Shanghai Liangxin electrical appliance Co., Ltd. of the Ndc1 series, after the two basic sources in the form of LC1. CJ45 from 6.3 to 800A19 current specifications, 10 kinds of models, the mechanical and electrical life of 10000000 times and 1000000 times, with a modular and fully plastic structure, there is a delay, coil surge suppression, mechanical interlocking and other accessories, in particular, the use of Ag-Ni (16A and below) or AgSnO2 (16A above), with environmental protection.

Installation and use of AC contactor

1 AC contactor operation problem

AC contactor is a widely used control appliance, mainly used to control motors and other electrical equipment operation and stop, an ordinary AC contactor in the attraction, the coil of the AC contactor still through the alternating current, power consumption is relatively large, so the heat coil, noise is relatively common, not only a waste of electricity can and coil insulation easily aging makes the AC contactor shortened life expectancy.

Function and using effect of energy saving module of 2 AC contactor

In an ordinary AC contactor is used for the energy saving module, reduces the AC contactor suction state power greatly, coil temperature will greatly reduced, the contactor coil insulation layer because of the high temperature aging, so as to prolong the service life of the contactor. The noise greatly reduced the operating state of AC contactor, the contactor to improve the use environment conditions. Ordinary AC contactor can only be rated voltage of 85% to 110% of the range, when the coil ends voltage higher than the rated voltage of 110%, AC contactor coil may be due to heat and burn, after the installation of this module in the contactor, AC contactor to withstand voltage fluctuations in power, in the case of high power supply voltage, AC contactor coil will not burn.

Join the module after the contactor sound crisp and powerful, attracting state current is only not the installation of the module of 10% ~ 40%, power-saving rate of 90% ~ 60%. And contactor noise reduced, for a long time to contactor attracting, the contactor coil surface without obvious temperature rise, even and cool feeling, to CJ20-400A contactor test, without energy-saving module (coil voltage 220V) contactor in the attraction of the reach a steady state when the voltage is 220V, current for 0.615A, noise is 52.5dB, temperature 105.2 DEG C, the installation module after the steady state is reached when the voltage is 220V, current 0.184A, noise is 36.6dB, 26.8 degrees Celsius temperature, seen in a power saving rate of 70%. By the above experiments can be seen: installing l AC contactor energy-saving module in the contactor coil circuit, the contactor current, noise and temperature rise decreased drastically. It is proved that the module of AC contactor with decrease coil loop current, reduce noise, reduce temperature rise.

Now Kang Bao county all street lamps have been installed in the module, a complete solution to the interference of the noise of the contactor at night when the residents of the interference, saving a lot of electricity.

Installation and application of energy saving module of 3 AC contactor

At the top of the module, there are two input terminals, and the lower part of the lower side of each have two output leads, the lower part of the module output wire connecting the terminal (A2, A1), the input terminal of the module to the end of the AC contactor control circuit.

Energy saving module of the working voltage of AC220V, the input terminal can only access the operation of the 220V power supply, access to the 380V power, but the output of this module can drive coil rated voltage 380V AC contactor, this point, please pay special attention to!

If the contactor coil voltage is 220V, the wire will be removed from the terminal, and then the output of the module is connected to the coil of the contactor. If the original contactor coil voltage is 380V, to put the module on the AC contactor coil circuit, but also the original control circuit two power lines in a root change received N line (the original control power line connecting two phase, voltage of 380V, now one of the strings instead received N line, enable the control voltage change 220V), if the original control circuit and rated voltage 380V indicator light, an intermediate relay, a time relay and so on element, but also the replacement of these components is the rated voltage is 220V element.

electric motor starter contactor

Starter

Control motor starting and stopping the use of electrical appliances. Motor starting, the starting current to exceed the motor rated current many times, starting current, the voltage of the line temporarily to be reduced. In case of large capacity, the voltage is lower, and it has little influence on the work of other electrical equipments on line. Therefore, the medium and small capacity AC motor can be used in direct starting mode. If the line voltage is reduced more, on the one hand, it will affect the operation of other equipments on the line. On the other hand, the starting torque of the motor will be reduced, the starting will be difficult, and even starting failure.

The starter is divided into two types, manual and automatic. The common use of a star delta starter in the manual starter of AC motor, which belongs to the starting mode of the buck. At the start, the winding is connected to the star, so that the applied voltage of each phase winding is reduced to the phase voltage to reduce the impact of the starting current. In the starting process, the three-phase winding is converted into a triangle by the method of triangle, and the starting of each phase voltage is raised to the line voltage. The manual starter of the DC motor is a series of current limiting resistance in the motor winding circuit to limit the starting current, and with the manual operation to cut series resistance, the speed of the DC motor is gradually increased, and the starting time of the whole series resistance is completed. The automatic operation of the starter is divided into two kinds of direct starting and decompression starting. The commonly used direct starter is electromagnetic starter, which has the function of loss of pressure and overload protection. Direct starters and two kinds of irreversible and reversible. The non reversible starter can only complete the starting and stopping of the motor; the reversible starter can accomplish the forward rotation starting, reverse rotation starting and stopping function. The automatic pressure relief starter has the self coupling decompression starter, the frequency sensitive starter and the integrated starter.

GV2-M circuit breakers for motors

Product brief:

GV2 motor protector for 3 extreme heat magnetic circuit breakers, designed for motor control and protection design, according to the standard of IEC 60947-2 and IEC 60947-4-1 for. Mainly used in AC 50Hz, rated voltage up to 415. The circuit of rated working current 0.1A-32A, as motor overload, short circuit, broken phase, blocking and three-phase unbalance protection, and not frequent starting, used as an isolator. GV2 motor protector adopts module structure, can conveniently install auxiliary contact, alarm contacts, under voltage release and shunt tripping device and other accessories.

Performance description:

1, when the motor circuit breaker to operate on its own can be manually controlled (can be controlled through a button or knob control), connecting the contactor can be remote control;

2, motor protection by integrated thermal relay circuit breaker;

3, all charged parts have been protected, can not be directly from the front panel touch;

4, with undervoltage release module, the circuit breaker can open under pressure conditions;

5, with sht module, disconnect the device can use the remote control;

6, installation of open type and close type motor circuit breaker control device can be used 3 padlocks locked in “N/C” position.

Advantage

Compact and concise, GV2 TeSys motor circuit breaker only 45mm wide, and according to the control type, breaking capacity, motor protection components and accessories

And so on the different performance and the function to carry on the classification.

vacuum contactors

Vacuum arc extinguishing chamber is used to connect and cut off the normal operating current, which is usually used to connect and disconnect the 6kV, 380V (1140V, 660V) AC motor.

Form

The vacuum contactor is composed of the vacuum arc extinguishing chamber and the operating mechanism. The vacuum arc extinguishing chamber has two functions, which are reliable and arc extinguishing through normal working current and frequent cutting off working current. But can not cut off the load current and short-circuit current. The operating mechanism is composed of a belt core holding coil and armature structure. The coil is energized, the armature contactor coil; attract, loss of power, disconnect contactor. The suction coil generally has two forms of DC and AC.

The vacuum chamber is made of glass or ceramic insulating material, and the vacuum degree is usually above 0.01Pa. Because of the air inside the shell, the contact distance can be very small, and the electric arc can be easily extinguished. The contact material is usually made of copper, antimony, osmium alloy etc.. Arc in arc chamber shield is, when the current is broken, condensation contact gap in the diffusion of metal vapor, contribute to the extinction, also can prevent metal vapor splashed on the insulating casing to reduce the insulation strength. The movable contact and the lower end of the casing are connected with the corrugated pipe, and the movable contact can be moved up and down and the movement can not leak.

The arc extinguishing ability of the vacuum contactor is good, the pressure resistance is good, the operating frequency is high, the life is long, and no electric arc spraying.

Vacuum contactor circuit diagram

Product is small, light weight, maintenance cycle is longer. The vacuum arc extinguishing chamber is very high. If the process is bad, the vacuum of the arc chamber is easy to fall. Contact material is not good, in the break current will appear “cut off” phenomenon, that is, the point of breaking current, due to the vacuum arc extinguishing ability is very strong, the arc current is not natural zero crossing, but from the current value of a sudden drop to zero, resulting in high voltage. Closure voltage will endanger the safe operation of electrical equipment.

How to choose a suitable AC contactor

Selection

Selection of AC contactor, the type of load and the reasonable selection of working parameters. Concrete into the following steps:

1 type of contactor

AC contactor is divided into one class, two class, three class and four class according to the load type, denoted as AC4, AC3, AC2 and AC1 respectively. The control object of a type of AC contactor is non sense or micro load, such as incandescent lamp, electric resistance furnace, etc. the two type of AC contactor is used for starting and stopping of winding induction motor. The typical application of three kinds of AC contactor is the operation and operation of squirrel cage induction motor.

2 selection of the rated parameters of the contactor

According to the controlled object and working parameters such as voltage, current, power, frequency and working system, etc..

1) the coil voltage of the contactor, generally should be lower for good, so that the insulation requirements can be reduced, the use of the more safe. But in order to facilitate and reduce the equipment, often according to the actual power grid voltage.

2) motor operating frequency is not high, such as compressor, water pump, fan, air conditioning, punch, etc., contactor rated current is greater than the rated current. Contactor type can choose CJ20, CJl0, etc..

3) of the heavy task type motor, such as machine main motor, lifting equipment, winches, crushing machine, such as. The average operation frequencies more than 100 times / min, running to the starting point, is the reverse brake, reverse connect brake state, can choose CJl0Z, CJl2 type contactor. In order to ensure the electric life, the contactor can be used for reducing the capacity. Selection, the contactor rated current greater than the motor rated current.

4) of severe motor tasks, such as printing machine, boring machine etc., the operating frequency is very high, up to 600 ~ 12000 times / h, often running for starting, reverse connect braking, reverse state, contactor roughly can be according to the electrical life and starting current selection, the contactor type selection and CJl2 CJl0Z etc..

5) in an AC circuit of capacitor input from the power grid or removed from the grid and selecting contactors switching surge current of capacitor should be considered. Generally, the rated current of the contactor can be selected according to the rated current of the capacitor 1.5 times, the model selection of CJ10, CJ20, etc..

6) in the control of the transformer, the size of the surge current should be considered. For example, AC arc welding, resistance welding, etc., generally can be rated current of 2 times the rated current of the transformer, the selection of CJl0, CJ20, etc..

7) for the electric heating equipment, such as electric resistance furnace, electric heater, the load of the cold state resistance is small, so the starting current corresponding to a large number of. When the contactor is used, it is not to be considered (starting current), and the load current of the rated current is selected. Model can choose CJl0, CJ20, etc..

8) due to the gas discharge lamp starting current, starting time, for the control of lighting equipment, can be rated current 1.1 to 1.4 times the selection of AC contactor, model CJl0, CJ20, etc..

9) contactor’s rated current is refers to the contactor in long-term work under the maximum allowable current, the duration is less than or equal to 8 hours and is installed on the open control panel, if the poor cooling conditions, the choice of contactor, rated current of a contactor according to the load current rating of 110% ~ 120% selected. For a long time working motor, because the film has no chance to get rid of, so that the contact resistance increases, resulting in more than the allowable temperature rise of contact. In the actual use, the rated current of the contactor can be reduced by 30%.

中文

中文