机械联锁接触器

- At 2015年11月23日 星期一

- By Jacky Zheng

- In Basic knowledge

0

0

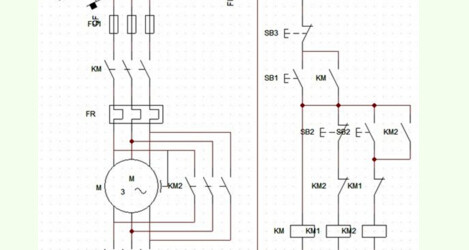

机械联锁接触器主要用于交流50Hz或60Hz,额定工作电压至660V、额定工作电流至95A以下的电路中,作电动机可逆控制用。它的机械联锁机构,保证了两台可逆接触器触头的转换的工作可靠性。

两只接触器组合在一起控制电机正反转的就叫可逆接触器。两只接触器之间安装的机构,叫机械连锁。如果没有这个装置,按下控制左边接触器的按钮同时在按下控制右边接触器的按钮,那两只接触器就会都吸合,那主回路就短路。这个装置就是防止两只接触器同时吸合的。

CJX2-N(LC2-D)系列可逆连锁交流接触器适用于交流50Hz或60Hz、电压至690V、电流至95A电路中,作电动机可逆控制用。它的机械联锁结构,保证了两台可逆接触器触头转换的可靠工作。

产品符合GB14048.4标准。

一些比较常用的型号有:

CJX2-09、CJX2-12、CJX2-18、CJX2-25、CJX2-32

CJX2-40、CJX2-50、CJX2-65、CJX2-80、CJX2-95

LC2-D09、LC2- D12、LC2- D18、LC2- D25、LC2- D32

LC2- D40、LC2- D50、LC2- D65、LC2- D80、LC2- D95

型号 额定工作电流400V, AV-3A 控制功率KW 辅助触头数量 备注

230V 400V 415V 440V 690V

CJX2-09N 9 2.2 4 4 4 5.5 NC 安装方式除螺钉, 安装外还备有35mm安装轨

CJX2-12N 12 3 5.5 5.5 5.5 7.5 NC

CJX2-18N 18 4 7.5 7.5 9 9 NC

CJX2-25N 25 5.5 11 11 11 15 NC

CJX2-32N 32 7.5 15 15 15 18.5 NC

CJX2-40N 40 11 18.5 18.5 22 30 NO+NC 除螺钉安装外还备有75mm安装轨

CJX2-50N 50 15 22 22 30 33 NO+NC

CJX2-63N 63 18.5 30 30 37 37 NO+NC

CJX2-80N 80 22 37 37 45 45 NO+NC

CJX2-95N 95 25 45 45 45 45 NO+NC

三:CJX2-N(LC2-D)可逆交流接触器外型与安装尺寸

QJX2系列星三角电机起动器

- At 2015年11月18日 星期三

- By Jacky Zheng

- In Basic knowledge

0

0

大功率电机起动电流很大,为避免大电流对线路造成冲击影响,将电机角接法运行改为星接法起动,转速达到一定惯性时再转为角接法运行称星/角起动,其起动电流为角接法的1/3。由3个接触器、1个时间继电器和按钮组成。

QJX2系列星三角减压起动器(以下简称起动器),适用于交流50Hz或60Hz,额定绝缘电压为660V(690V),在AC-3类别使用下额定工作电压为380V、功率为80KW及以下的三相鼠笼型感应电动机,用于控制定子绕组由“星形”至“三角”换接起动及停止。组装相应规格的热继电器后,可对电动机及有关电路的过载保护。

本起动器和LC3-D、QJX4具有相同功能规格可等同互换使用。

电机起动器(Motor Starter)的作用和原理分别是:

1、作用:

电机启动器,是用于辅助电机启动的设备,使电机启动平稳,对电网的冲击小,还能实现对电机的软停车、制动、过载和缺相保护等。电机启动器主要用于大型电机和异步电机中。

2、工作原理:

板间的距离使液体电阻阻值在起动过程中始终满足电机机械特性对串入电阻值的要求,从而使电动机获得最大起动转矩及最小起动电流,进而平稳起动。具体工作过程是:主电机启动时,动极板在一个小功率传动机构系统的带动下缓慢移动,改变两极板之间的距离,使串入转子回路的液体电阻阻值变化满足上述条件,电机转速升高。当两极板之间距离最小时,电机转速达到额定转速,将液体电阻短接,完成起动过程,转入运行状态。

GV2ME系列电机保护断路器

- At 2015年11月07日 星期六

- By Jacky Zheng

- In Basic knowledge

0

0

电机保护器的作用是给电机全面的保护,在电机出现过载、缺相、堵转、短路、过压、欠压、漏电、三相不平衡、过热、轴承磨损、定转子偏心时,予以报警或保护的装置。

电机保护器的常见类型

1、热继电器:普通小容量交流电机,工作条件良好,不存在频繁启动等恶劣工况的场合;由于精度较差,可靠性不能保证,不推荐使用。

2、电子型:检测三相电流值,整定电流值采用电位器或拔码开关,电路一般采用模拟式,采用反时限或定时限工作特性。保护功能包括过载、缺相、堵转等,故障类型采用指示灯显示,运行电量采用数码管显示。

3、智能型:检测三相电流值,保护器使用单片机,实现电机智能化综合保护,集保护、测量、通讯、显示为一体。整定电流采用数字设定,通过操作面板按钮来操作,用户可以根据电机具体情况在现场对各种参数修正设定;采用数码管作为显示窗口,或采用大屏幕液晶显示,能支持多种通讯协议,如ModBUS、ProfiBUS等,价格相对较高,用于较重要场合;高压电机保护均采用智能型保护装置。

4、热保护型:在电机中埋入热元件,根据电动机绕组的温度进行保护,保护效果好;但电机容量较大时,需与电流监测型配合使用,避免电机堵转时温度急剧上升时,由于测温元件的滞后性,导致电机绕组受损。

5、磁场温度检测型:在电机中埋入磁场检测线圈和测温元件,根据电机内部旋转磁场的变化和温度的变化进行保护,主要功能包括过载、堵转、缺相、过热保护和磨损监测,保护功能完善,缺点是需在电机内部安装磁场检测线圈和温度传感器。

施耐德交流接触器LC1D系列

- At 2015年11月03日 星期二

- By Jacky Zheng

- In Basic knowledge

0

0

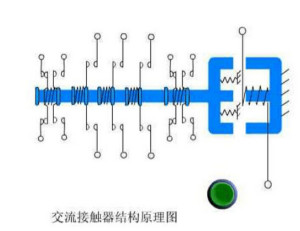

LC1-D09M7C施耐德交流接触器广泛用作电力的开断和控制电路。它利用主接点来开闭电路,用辅助接点来执行控制指令。主接点一般只有常开接点,而辅助接点常有两对具有常开和常闭功能的接点,小型的接触器也经常作为中间继电器配合主电路使用。 交流接触器的接点,由银钨合金制成,具有良好的导电性和耐高温烧蚀性。

• 接触器可组成机械可逆联锁磁力起动器,星三角减压起动器

• 接触器为防护式,动作结构为直动式,触头为双断点

• 具有体积小,重量轻、功耗低、寿命长、安全可靠等特点

• 可根据用户选用增加辅助触头组、空气延时头等组合多种派生系列产品

• 安装时,应该按规定条件安装,接触器线圈的接线端子A1符合应朝上方,符合人的视觉习惯

• 对有金属安装底板的接触器要妥善接地

• 接线端螺钉应拧紧,检查接线正确无误后,应在主触头不带电情况下,先使吸引线圈通电分合数次,试验动作可靠后,才能投入使用

• 使用时如发现有不正常噪音,可能是铁芯极面上有污物,请擦净极面

• 使用中,应定期检查产品各部件,要求可动部位不卡住,紧固件无松脱,零部件如有损坏,应及时更换

电动汽车用直流接触器

- At 2015年10月26日 星期一

- By Jacky Zheng

- In 技术

0

0

电动车直流接触器是主要是用来控制电动机开关用的;

该接触器采用模块化设计,可以以最少的零件组装出顾客所需要的触点路数以及客户所需要的触点形式(常开,常闭和转换);该系列产品触点开断电压高,并采用横吹磁场灭弧,最高开断电压可达到220VDC.产品适用于程控电源或不间断电源系统,叉车,电动车,工程机械系统。

交流接触器国内外主要公司产品概况

- At 2015年10月19日 星期一

- By Jacky Zheng

- In Basic knowledge

0

0

1.ABB公司的B系列、A系列20世纪80年代初,曾由上海人民电器厂、北京低压电器厂作为生产许可形式,技术引进的ABB公司的B系列具有初步模块化结构;之后,又推出了EB、EH系列;90年代推出了A系列。A系列接触器有9~1050A22个电流等级,8种机型,适用的环境温度为:-40℃~70℃,是该接触器的特点。

2.富士公司的SC-E系列SC-E系列是常熟开关制造厂有限公司与富士公司合资的产品,有9~800A18个电流等级,10种机型。除了模块化等特点外,体积小是其亮点。例如,额定电流50A的SC-E25外形尺寸为54mm×90mm×96mm,仅为同电流等级ABB公司产品A50D的50.6%,是施耐德公司产品LC1-D50的38.5%,具有高可靠的接触性能(达DC5V,3mA)。

3施耐德公司的LC1-D系列20世纪80年代前期,天水213机床电器厂引进了施耐德公司的LC1-D系列接触器,是最早进入我国的接触器之一。当时,LC1按电流大小分9~95A的D系列和115~780A的F系列。近年又推出了包含9~620A20个电流等级,8种机型的LC1-D系列。该产品是模块化结构的典型代表,进一步减小了飞弧距离,提高了防护等级,操作频率可高达3600次/h(小电流规格)或2400次/h(大电流规格)。

4西门子公司的3RT系列西门子公司的3RT系列接触器继承了3TB的寿命高、线圈模块化、便于更换的优点,且实现了全塑化及高防护能力(IP2x)。全系列有7~500A19个电流等级,7种机型,机械寿命最高可达3000万次,线圈平均功耗低是其易于同类的特点。

5国内CJ40、CJ45系列等产品该系列产品主要由上海电器科学研究所主导开发的,杭州之江开关厂、上海人民电器厂、天津百利、正泰电器有限公司等生产的CJ40、CJ45系列;天水213厂引进生产的GSC1系列;上海良信电器股份有限公司的NDC1系列等,后两者基本源于LC1的形式。CJ45从6.3~800A19个电流规格,10种机型,机电寿命分别达到1000万次和100万次,具有模块化和全塑化结构,有延时辅触、线圈浪涌抑制、机械连锁等齐全的附件模块,特别是触头采用Ag-Ni(16A及以下)或AgSnO2(16A以上),具有环保意义。

交流接触器辅助触点识别方法

- At 2015年10月10日 星期六

- By Jacky Zheng

- In 技术

0

0

1. 标有NO和NC

NO是英文normal open(常开)的缩写,NC是normal close(常闭)的缩写。

2. 标有数字序号11或12等

后面一位数(1、2)代表常闭触头,(3、4)则代表常开触头,类似的。还有(5、6)、(7、8)代表时间继电器的延时常闭、常开触头组。

3. 交流接触器辅助触点两端是否可以直接接220V交流电?

可以,事实上许多电路的指示灯就是接的220v。

4.辅助触点的作用

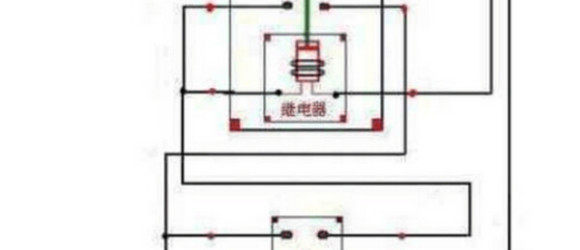

交流接触器有3对主触点,上面的3个接线端子是接电源的,下边的3个接线端子是接用电设备的,吸合线圈接控制回路,当吸合线圈得电铁芯产生磁性,吸合衔铁,主触点接合,用电设备通电工作。另外还有辅助的常开及常闭触电,可用作自锁和互锁控制用。用下面这张图说明常开触点在控制回路中的作用

5.常开常闭的识别方法

用万用表的电阻档测量(不带电的情况下测量)一般情况上下为一组,顾名思义通路(阻值为0或接近0)的为常闭,开路(阻值无穷大)的为常开。

交流接触器的维护和检查

- At 2015年10月03日 星期六

- By Jacky Zheng

- In 常见问题

0

0

交流接触器的运行检查项目

1.检查最大负荷电流是否超过接触器规定的负荷值。

2.检查接触器线圈温升是否低于65度。

3.监听接触器内有无放电声以及电磁系统有无过大的噪声和过热现象。

4.检查触头系统和连接点有无过热烧损现象。

5. 检查灭弧罩是否完整,如有损坏应更换后再运行。

6.检修触头系统,用细挫或细砂纸打光接触面,保持触头原有状态,调整接触面及接触压力,以保持三相同时接触,触头烧损严重的应更换。

7.检查灭弧罩内部附件的完好性,并清擦烟痕等杂质。

8. 检查联动机构的绝缘状况,并检查是否有变形、移位及松脱现象。

9.检查吸合铁芯的接触表面是否光洁,是否有凹凸不平或油污情况,短路环是否断裂或过度氧化及脱出情况,吸合是否良好,断开后,是否返回到正常位置。

10.交流接触器的清洁及周围环境的检查。

11交流接触器的分、合信号指示是否与电路状态相符。

12.电磁线圈有无过热现象,电磁铁上的短路环有无脱出和损伤现象。

13.辅助触点有无烧蚀现象。

14.铁芯吸合是否良好,有无较大的噪声,断开后是否能返回到正常位置。

15.周围的环境有无变化,有无不利于接触器正常运行的因素,如振动过大、通风不良、导电尘埃等。

交流接触器安装及使用注意那些问题

- At 2015年09月21日 星期一

- By Jacky Zheng

- In Basic knowledge

0

0

1 交流接触器运行中的问题

交流接触器是一种应用广泛的控制电器,主要用于控制电动机等用电设备的运行和停止,普通的交流接触器在吸合后,交流接触器的线圈里仍然通着交流电,功耗比较大,所以线圈发热,噪声大比较普遍,不仅浪费电能而且线圈的绝缘容易老化使交流接触器的寿命缩短。

2 交流接触器节能模块的功能与使用效果

在普通交流接触器上使用节能此模块后,交流接触器吸合状态下功耗大幅度降低,线圈温度也会大大降低,可以使接触器线圈的绝缘层不因为高温而老化,从而延长接触器的使用寿命。交流接触器吸合状态下噪音大幅度降低,改善接触器使用场所的环境条件。普通交流接触器一般只能在线圈额定电压85%~110%的范围内工作,当线圈两端电压高于额定电压的110%时,交流接触器线圈有可能会因为发热而烧毁,在接触器上加装此模块后,交流接触器承受电压波动的能力增强,在操作电源电压过高的情况下,交流接触器线圈也不会因为发热而烧毁。

加入该模块后接触器吸合的声音清脆有力,吸合状态下的电流仅为不加装模块时的10%~40%,节电率为90%~60%。而且接触器吸合后的噪音降低,长时间使接触器保持吸合,接触器线圈表面无明显的温升,甚至还有凉的感觉,对CJ20-400A接触器试验,未加节能模块(线圈电压220V)接触器在吸合后达到稳定状态时的电压为220V、电流为0.615A、噪音为52.5dB、温度为105.2℃,安装模块后,达到稳定状态时的电压为220V、电流为0.184A、噪音为36.6dB、温度为26.8℃,视在功率的节电率为70%。由以上试验可以看出:在接触器线圈回路里加装QCJ交流接触器节能模块后,接触器的电流、噪音、温升均大幅下降,证明模块对交流接触器具有减小线圈回路电流、降低噪音、降低温升的作用。

现在康保县所有路灯已经安装了该模块,彻底解决了接触器晚上工作时噪声对居民的干扰,节省了大量电费。

3 交流接触器节能模块的安装应用

在模块的顶部有两个输入接线端子,下部两侧各有两个输出导线,将模块下部的两根输出导线接交流接触器线圈的接线端(A1、A2),将模块顶端的输入接线端接交流接触器的控制电路。

节能模块的工作电压为AC220V,输入端只能接入220V的操作电源,严禁接入380V电源,但本模块的输出却可以驱动线圈额定电压为380V的交流接触器,此点请特别注意!

具体操作方法如果接触器线圈电压为220V,则只需将原接交流接触器线圈的导线从接线端子上拆下,接到本模块的输入端子上,再把本模块的输出导线接交流接触器的线圈即可(即把本模块串接到接触器的线圈回路里)。如果原接触器线圈电压为380V,则要把本模块串到交流接触器的线圈回路里,同时还要把原控制线路两根电源线中的一根改接到工作N线上(原来的控制电源线接两根相线,电压为380V,现把其中的一根线改接到工作N线上,使控制电压改变为220V),如果原控制线路里还有额定电压为380V的指示灯、中间继电器、时间继电器等元件,还要把这些元件更换为额定电压为220V的元件。

电机起动器接触器

- At 2015年09月16日 星期三

- By Jacky Zheng

- In Basic knowledge

0

0

起动器

控制电动机起动和停止用的电器。电动机起动时,起动电流要超过电动机额定电流很多倍,起动电流大时线路的电压暂时要有所降低。线路容量较大的情况下电压降低不多,对线路上的其他电器设备的工作影响不大,因此,中小容量的交流电动机可采用直接起动方式。如果线路电压降低较多,一方面会影响线路上其他设备的运行,另一方面电动机的起动转矩将减小,起动发生困难,甚至起动失败,因此,需要采用起动器。

起动器按操作方式分为手动和自动两类。交流电动机的手动起动器中比较常用的有星-三角起动器,它属于降压起动方式。在起动时,先将交流三相电动机的绕组接成星形,使每相绕组的外加电压降低为相电压,以减小起动电流的冲击。起动过程中手动操作将三相绕组转换成三角形接法,将每相电压升高到线电压后完成起动。直流电动机的手动起动器是在电机的绕组电路中串入限流电阻,以限制起动电流,用手动操作逐段地切除串联电阻,直流电动机的转速逐步上升,直至全部串联电阻切除后起动完成。自动操作起动器又分为直接起动和减压起动两种。常用的直接起动器是电磁起动器,具有失压和过载保护功能。直接起动器又分不可逆和可逆两种。不可逆起动器只能完成电动机的起动和停止功能;可逆起动器可完成正向旋转起动、反向旋转起动及停止功能。自动减压起动器有自耦减压起动器、频敏起动器和综合起动器等。

English

English